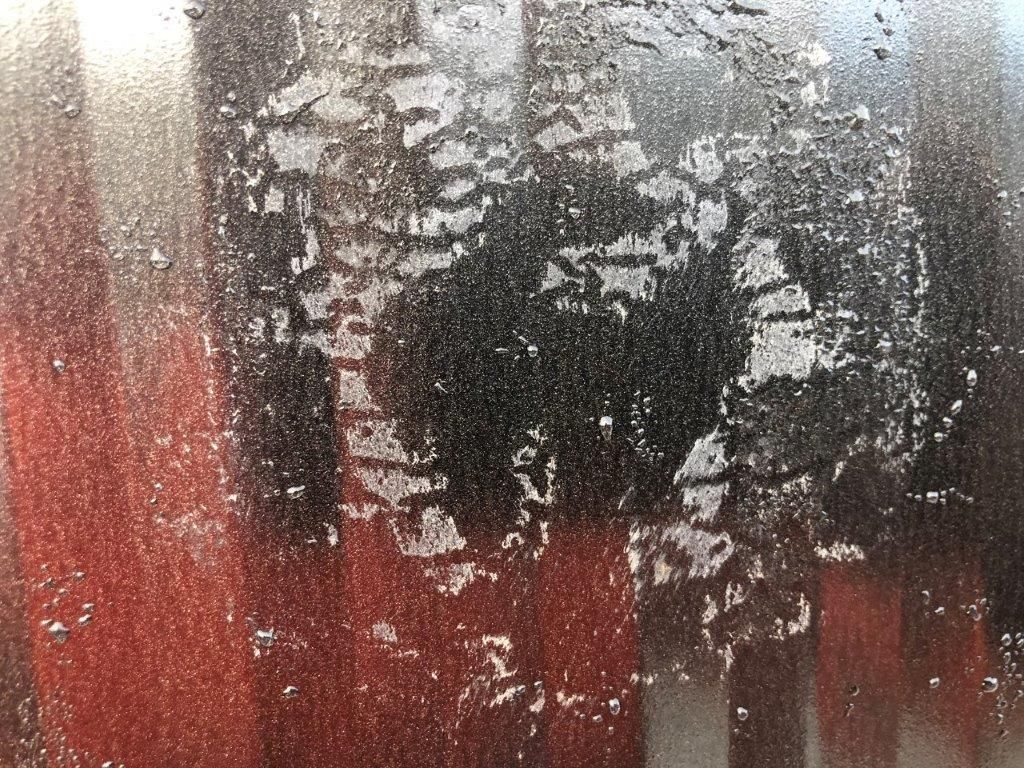

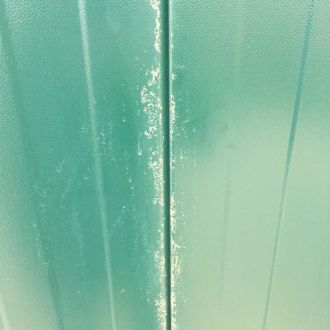

Professional removal of PUR residues

PUR residues are rather aggressive and have adhesive properties. As a result, they are harmful to roof and façade panels, and hard to remove. Van Heemskerk can professionally remove PUR residues from your panel or sheeting.

We expertly and professionally remove PUR residues from sandwich panels and sheeting by all well-known global manufacturers and suppliers, including Kingspan, Joris Ide, Falk, Arcelor, etc. Thanks to our repair method, we can virtually invisibly repair your façade or roof panel on the spot, which means the panel won't need to be replaced.

When it comes to damage repair techniques, Van Heemskerk is a master. We only work with high-quality, proven paint systems, derived, among others, from the automotive sector. Van Heemskerk has proven itself as a leading expert in damage repairs to company buildings and properties.

Would you like to know more about the professional removal of PUR residues? Would you like to request a cost indication? Feel free to contact us.

Why Van Heemskerk?

-

Our organisation is constantly developing innovative damage repair solutions.

-

Onze organisatie is voordurend bezig met innovatieve oplossingen wat betreft schadeherstel.

-

Repairs take place on-site, which means your panel with PUR residues usually won’t have to be replaced.

-

Our services are recommended by many well-known panel manufacturers and suppliers.

-

We are familiar with all types of panels, coatings and profiles.

-

Your façade or roof will be restored to its original condition.

-

We always offer a solution for your damage, either through repairs or replacement.

Normally, unless their size and position are too extreme, PUR residues can be spotlessly removed. So far, we've always been able to fix everything.

PUR has adhesive properties, forming a rock-solid bond with coatings and all sorts of other substrates. Sometimes, if you're lucky, you can use a sharp knife in an out-of-sight spot to scrape the residue off. However, PUR usually leaves a stain. PUR cleaners are highly aggressive. Most coatings are polyurethane-based, which means the cleaner will also affect the substrate!

We start by sanding down the PUR. Afterwards, we prime the panel and respray it in the appropriate colour. Thus far, this has proved the only effective approach. There are no other tools or methods.

9 out of 10 times, panels and profiles feature a coil coating, which is also known as pre-painted steel or aluminium. This could be a colorcoat prisma, PVDF, silicon polyester, or an HPS Plastisol coating, among others. Coil coating is a factory process involving extreme heat. As such, it cannot be applied for repairs.

The products we use are derived from the automotive sector and were specifically designed for repairs to sandwich panels and profiles. The paints seamlessly fit the applied coil coat when it comes to durability and appearance. We are familiar with all types of coating systems and always have the most common colours in stock.

No two colours or buildings are the same. Even if they have the same RAL code or name, every new coil will have a different colour or appearance. This is because most pigments for paints and lacquers are derived from nature, so their properties may differ from shipment to shipment. This phenomenon has an extra dimension in case of metallics, which professionals call “flop”. Flop refers to the way the metallic particles are positioned on the surface. This can result in a darker or lighter effect. It's not unlike a high-pile rug: the colour doesn't change, but you get lighter or darker spots depending on the position of the piles.

Properties and sheeting panels suffer from discolouration over the years. One of our specialisations is “retinting”. This means we use the right pigments to touch up the damage, so it matches the existing colour.

Van Heemskerk is an expert in mixing the most suitable colour during repairs. We strive for customer satisfaction by making our repairs “virtually invisible!”

Yes, our service covers a wide range of applications, including repairs to aluminium frames and doors. Please refer to the other parts of this website for more information. We also work with composite and wooden constructions. We can usually offer a solution, even if this is not necessarily listed on our website.

We are familiar with:

- Kingspan

- SAB

- Hoesch / Hobone

- Arcelor Mittal

- Joris Ide

- Plaum

- Trimo

- Cladding Point

- Falk

- Van Delft Profielen

- Salzgitter Bauelemente

- Itapanelli

- Hardeman Veenendaal

- Isocab

- Brucha

- Paroc

- Unisol

- KIM

- Beckers

- Colpro

- Holland groep

- Metecno

- Rex panels

We work with the most common coating systems by all manufacturers and suppliers, including:

- Prisma coating

- PVDF coating

- Terracoat

- SP and polyester coating

- Polyurethane coating

- HPS coating, HPS ultra coating

- Colorcoat

- Corus colors

- Nova coatings

- British steel colors

- Swedish steel coatings

- Armatone coatings

- Plastisol leather-grain coating,

- Armatec coating

- Spectrum coating

- Benchmark coating

- Hairexcel coating

- Metallic coating

- Mother-of-pearl coating

- Euromax coating

- Hardeman Coatings

- Falk panels and coatings

- Foodsafe coating

- Interior coating

- XL forte coating

- Vinyl coating

- Leather-grain plastisol

We work for well-known panel manufacturers, property owners or tenants, property managers, installation companies, construction companies and private individuals.

We operate both within the Netherlands and abroad. Every day, we perform our activities throughout the Netherlands, Belgium and Germany. We also have projects far beyond this scope, such as in North and South America and the Middle East.

It is hard to estimate the costs in advance. They depend on a variety of factors, such as size, lighting, accessibility, paint type and local circumstances.

The price is also affected by the costs of replacement, dismantling and removal of the surrounding construction, which can cause damage, leaks etc. Sandwich panels are often attached with hidden fasteners and cannot simply be removed. On top of that, new deliveries almost invariably differ in colour, which means that repairs and spraying are often a more affordable option.

Contact one of our experts for non-binding information on the possibilities. We are happy to help you!

It's easiest to contact the regional expert in question via email. You can find more information about this on the right-hand side of this page. Please add pictures.

You could also fill out the web form. In that case, we will contact you soon.

It is difficult to make an accurate assessment based on a picture, so we regularly visit locations throughout the Netherlands, Belgium and Germany. This means we are likely to be able to drop by and take a look at your project.

Other services